Engineering for Performance.

In the world of high-performance heat exchangers, technical expertise, hands-on experience, and a passion for innovation are essential. At Mezzo Technologies, our team excels at all three, allowing us to push the boundaries of what’s possible and empower our clients to achieve even greater outcomes, partnering together every step of the way.

The New Standard in Expectations

We are laser-focused on quality, and our team holds themselves to the highest of expectations. Meeting your performance goals becomes personal to us, and we do what it takes to design with intention, test with rigor, and ensure results.

We aid in new product development, and product improvements/sustaining engineering, guiding you through the process, every step of the way.

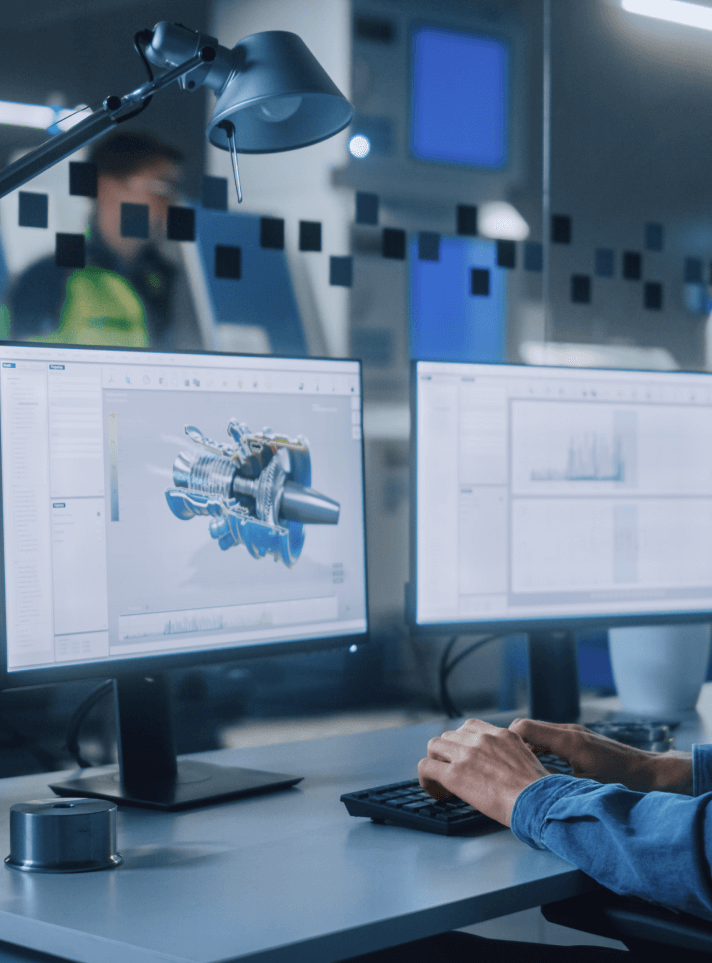

Advanced CAD

Every new design starts with a concept for the unit’s space claim, mechanical interfaces, structural design, and manifold design which we refine into a CAD file.

Flow Analysis

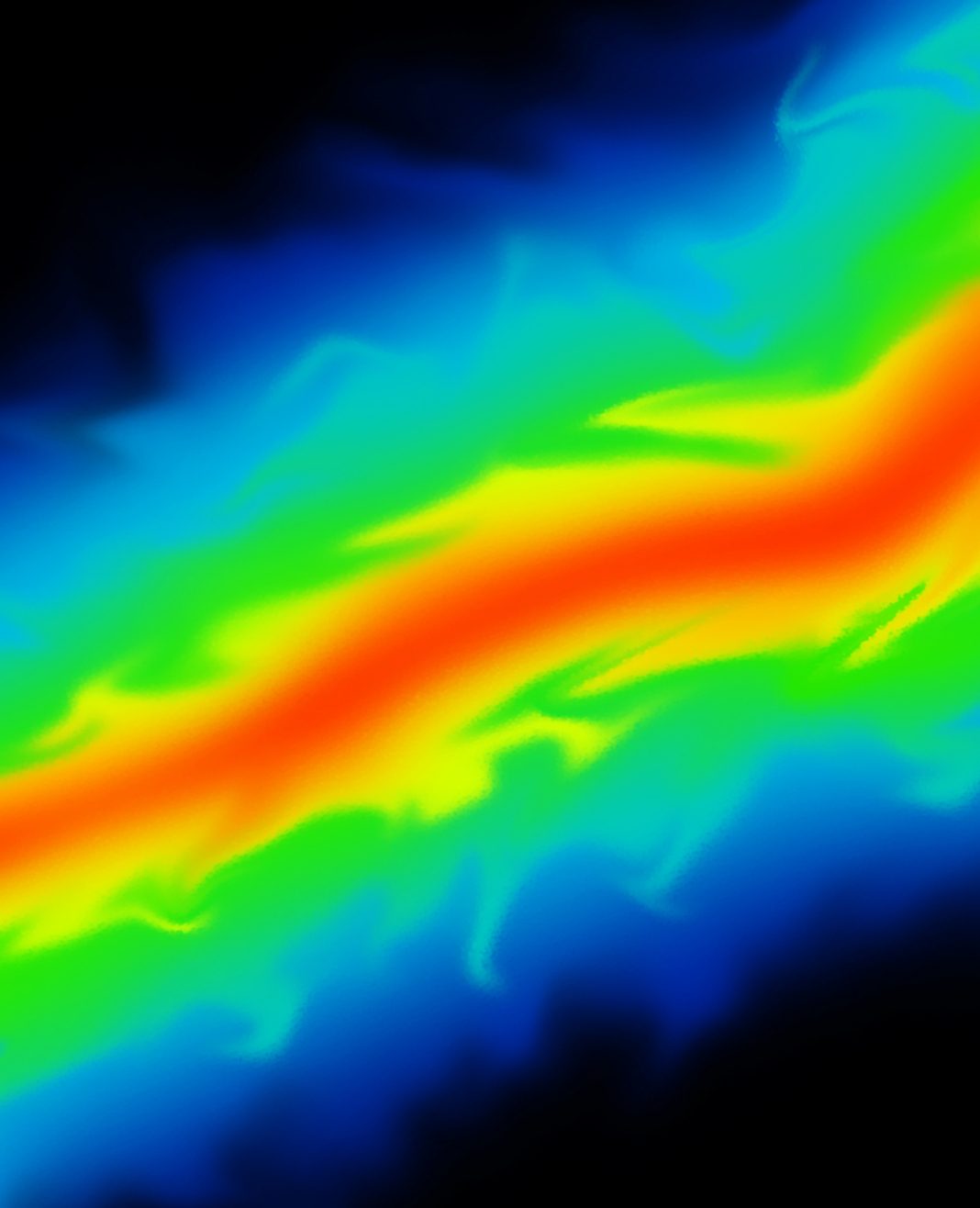

Once the conceptual design is complete, a Computational Fluid Dynamics (CFD) analysis is typically performed to optimize the heat exchanger’s manifold design. We explore the expected flow distribution and resulting temperatures throughout the microtube core to ensure no performance loss and adjust design if needed.

Thermal Analysis

Our proprietary thermal performance modelling software generates and processes massive sets of performance data for heat exchanger designs simultaneously. We can quickly simulate entire thermal systems, optimize heat exchanger designs, or look at details such as temperature gradients, metal temperatures, or heat transfer in discrete parts

of the core.

If resulting temperature gradients in the unit are very large and identified as a structural issue, our proprietary software will generate a temperature field for the unit, which can then be used in further Finite Element Analysis (FEA).

Structural Analysis

We use structural FEA to refine design and verify we’re meeting your design goals. Structural FEA can improve mechanical features or guide final material selection, ensuring that both stress and deflection are acceptable.

Next-Level Research & Development

Mezzo has spent fifteen years developing process to efficiently design and manufacture microtube heat exchangers. Particular expertise exists with respect to joining tubes to tubesheets, and Mezzo believes its approaches are the most dependable and cost-effective in the industry.

- Our team is transparent, upfront, and realistic about results throughout the entire process.

- We aim for no surprises – just reliable, powerful performance.

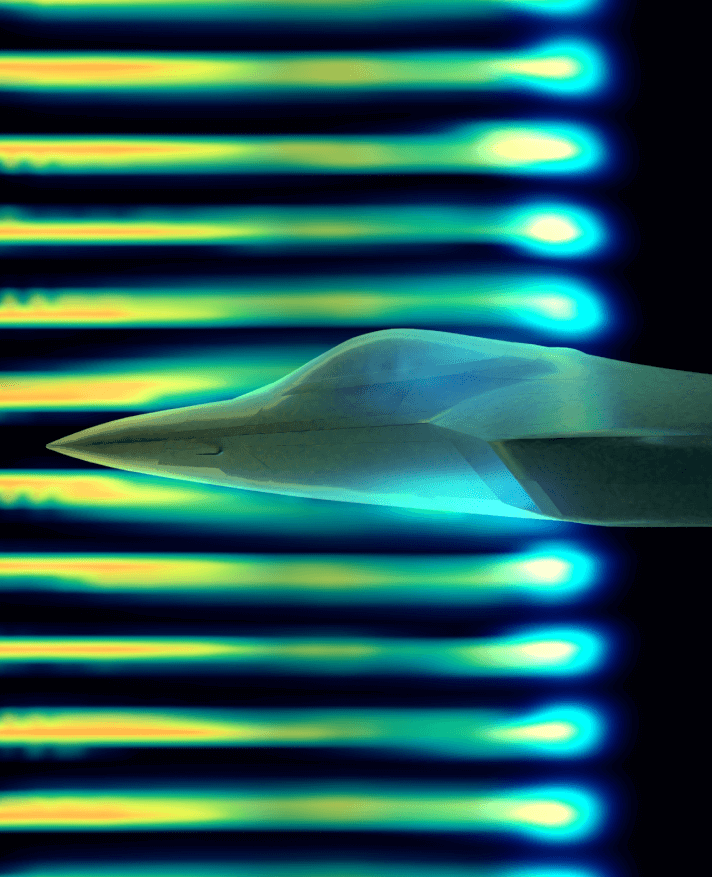

Wind Tunnel Testing & Correlations Development

Mezzo’s in-house performance models rely on empirical convection and flow friction correlations. Because no other company uses tubes in the same way, we’ve developed our own correlations to fully understand the heat transfer and frictional characteristics of flows over our tube cores.

Through extensive and continuous wind tunnel testing of new tube patterns and validation of established tube patterns, we can create new designs to precisely meet and exceed your performance targets.

In-House Manufacturing Expertise

Our team specializes in precision manufacturing for highly regulated industries. With proprietary intellectual property covering every stage of design and manufacturing, we deliver top-quality products with reliability that you can count on.

Your team at Mezzo handles not only engineering and design, but also manufacturing and assembly in-house, ensuring complete control over the end-to-end production process.

Making Waves

At Mezzo Technologies our technical advantage becomes your competitive advantage.

Meet the team you’ll be partnering with.