Push the Limits of Performance.

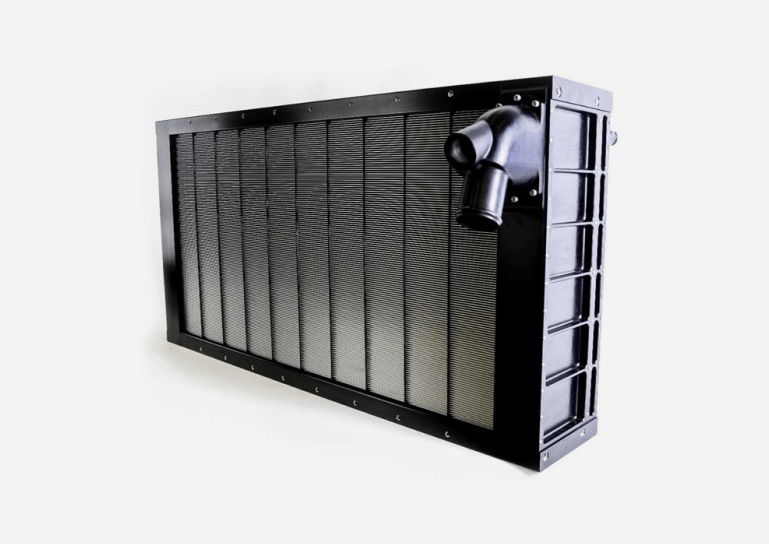

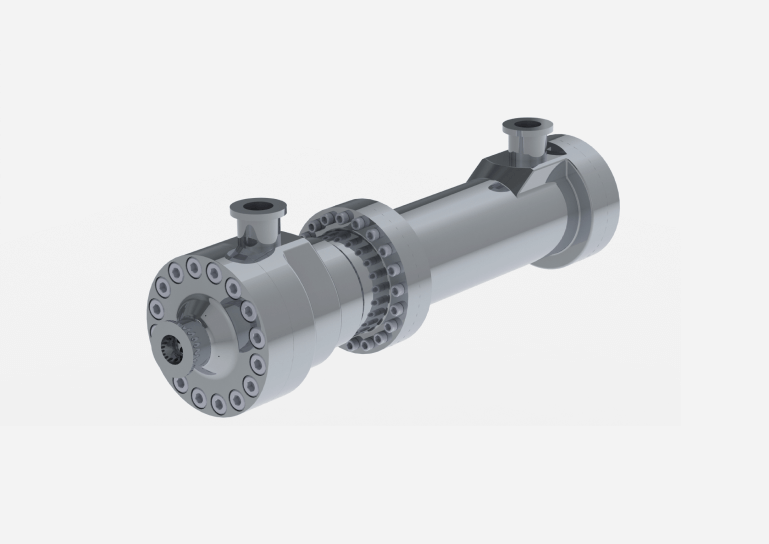

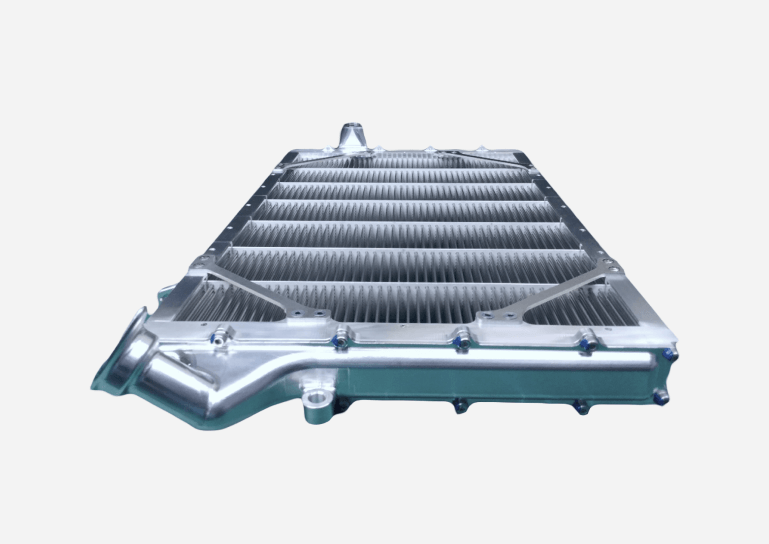

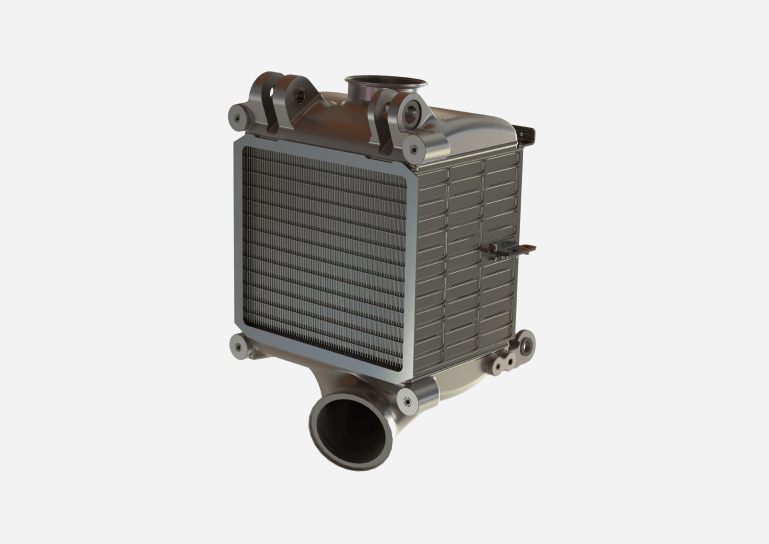

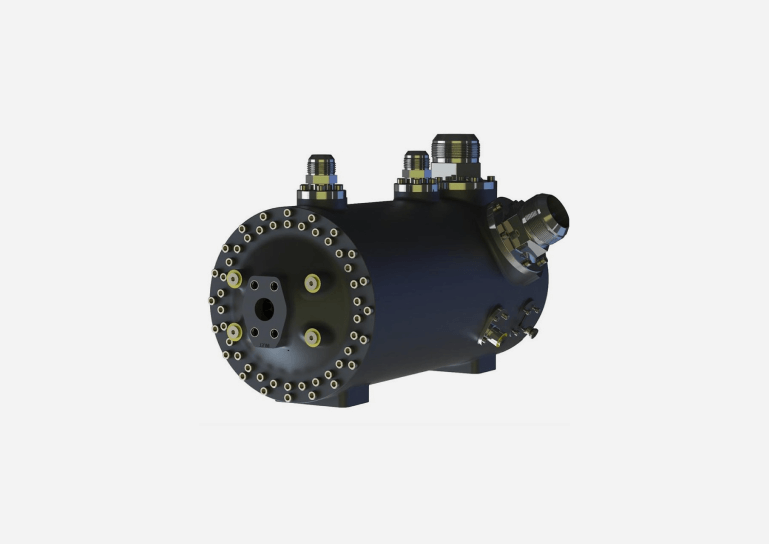

Solving complex thermal management challenges in extreme environments – technically advanced, high-performance custom microtube heat exchangers

Custom Microtube Technologies

At Mezzo Technologies, our highly experienced team of engineers solves complex thermal management challenges while elevating product performance – day in and day out. Our deep bench of innovators design, engineer, test, and manufacture custom heat exchanger solutions.

Whether you’re engineering a new product or evolving one, our unique technical competencies become yours on day one.

We lead with transparency, reliability, and accountability, and deliver unmatched innovation.

Give us your toughest challenge. We’re ready for it.

Microtube Heat Exchangers:

Extreme Environments, Extreme Performance

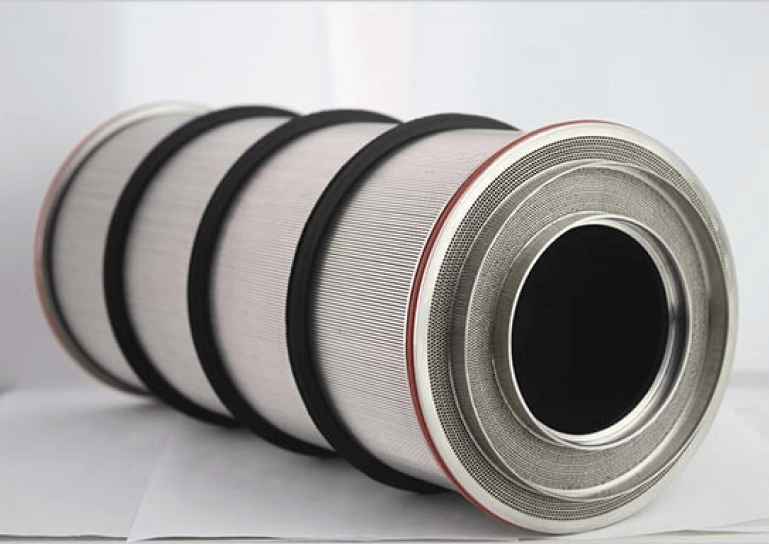

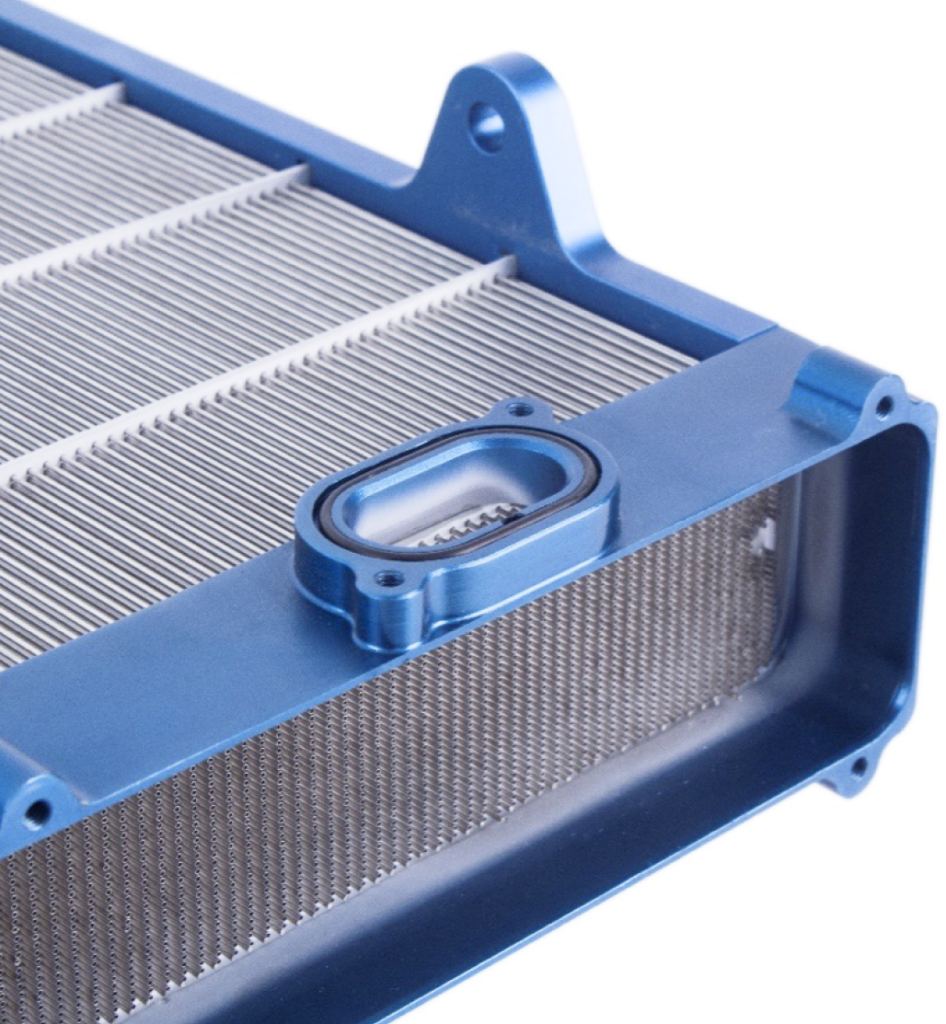

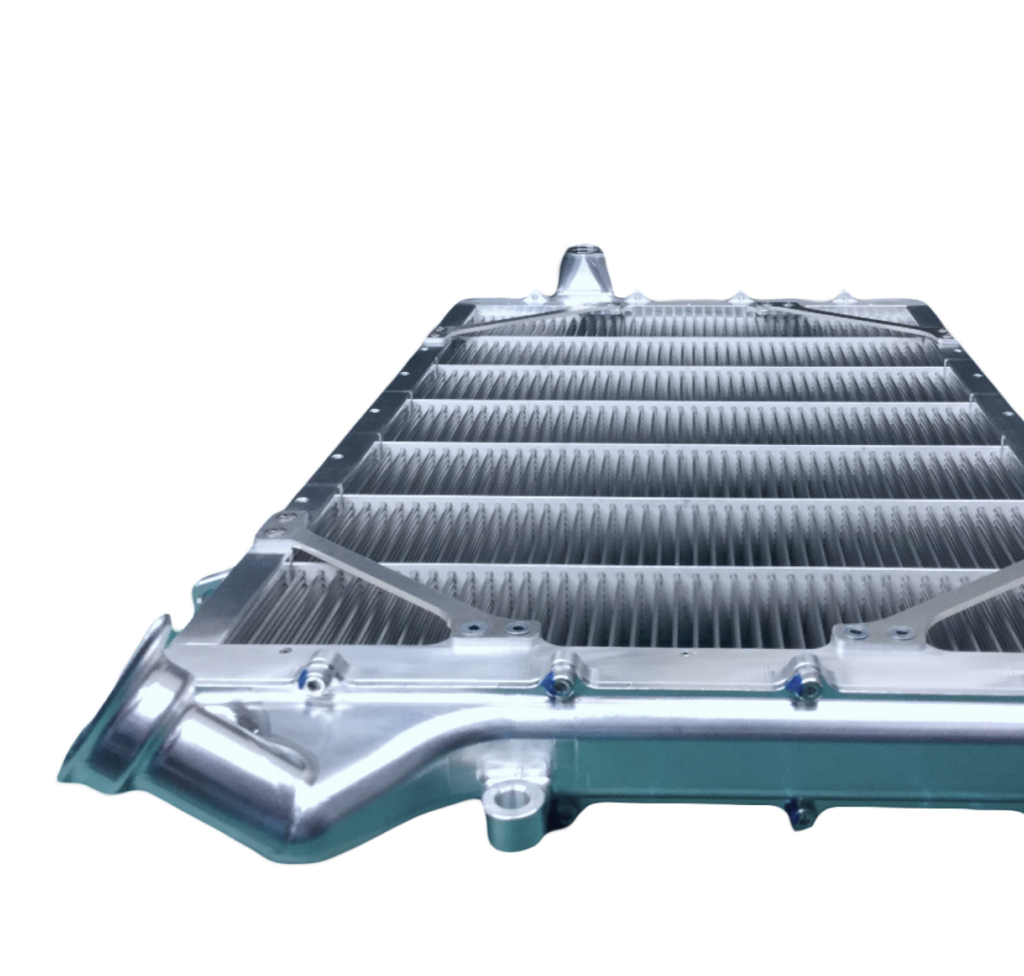

Microtubes are scientifically and technically engineered to be smaller, more compact, and perform better – providing a new level of high performance, far exceeding what’s possible for traditional heat exchangers.

- Compact & Lightweight

- Resistant to Air-Side Fouling

-

Optimal in High Pressure &

High Temperature Applications - Reliable & Durable

- Aerodynamic

- Corrosion Resistant

What’s Next:

The Cooling Technology of the Future

Microtube heat exchangers provide innovative solutions across a wide variety of applications and industries that are continually expanding.

AEROSPACE

SPACE

Directed energy

Removal of considerable waste heat to meet aggressive thermal management targets.

MODULAR NUCLEAR

Military

Mezzo microtubes deliver high-performance and robust cooling systems that consume minimal fan power.

AUTOMOTIVE RACING

Mezzo manufactures microtube heat exchangers for some of the most demanding customers in automotive racing; lightweight, high-performance solutions drive faster lap times.

In-House Expertise & Manufacturing, Long-term Partnerships

With Mezzo you’ll get tight control of quality, timelines, and costs with in-house IP and manufacturing. Our expertise and real-world experience in highly regulated, precision industries not only make us different but allows us to move fast. Whether you need quick turn prototyping or high-volume production, we are transparent, straightforward, accountable, and personally invested in each project.

We aim for no surprises – just reliable, powerful performance.

A Signia Aerospace Company

Mezzo Technologies is proud to be part of Signia Aerospace, a trusted partner in the innovation, manufacture, and delivery of highly specialized aircraft systems and components. Our depth of expertise and unique pool of resources allows us to act as an integrated, nimble partner in the design, manufacture, delivery, and service of highly specialized aircraft systems and components.